Design Optimization with Genetic Algorithm (DOGA)

Published:

This project focus on communicable and reusable computational design tools for industrial design. We propose a software based on SolidWorks, and provide interactive tools for both the model and color design of products. The design tools are driven by Genetic Algorithm (GA). The GA is based on computational analogy of biological process of natural selection. By defining some general metrics for individual (a product), the population (a set of product candidates) gradually evolves towards desirable directions in design space. Designers can interfere the evolve process by selecting desirable individuals. This allows features in the selected individuals are very likely preserved and interleaved during exploration of design space.

GA is a optimization method suitable for solving both constrained and unconstrained optimization problems. It is natural for design optimization for being inclusive to complex, unclear and multi-goal characteristics of design activities. The evolving process for product design optimization consists four stages:

1 Initialize product candidates with pre-defined parameters

Repeat evolve

2 Select a subset of candidates in evolution

3 Produce new product candidates by interchanging (some of) parameters among candidates

4 Trigger random flips in binary format of parameter value

Until reach desired design goal

The design optimization with GA (DOGA) defines a design space with pre-defined parameters. Idealy, these parameters have both irreducible complexity [1] that a biological system could not serve any useful function if any of these arguments were removed, and specified complexity [1] that match some patterns recognized by an intelligent agent but improbable match any patterns arise by natural causes. The interchange among parameter subsets as well as random flips can re-define an individual in the design space, and a novel product constrained under pre-defined parameters can be created. A DOGA example of Porcelain style design is shown below. The evovable parameters are numerical elements of the perceivable “style”, which are defined as pixel values in computer vision. After 5 generations (right), it is intuitive that new individual products are generated, and styles of product candidates converge to specific patterns.

Left(Upper): Initial polulation. Right(Bottom): The 5-th generation population.

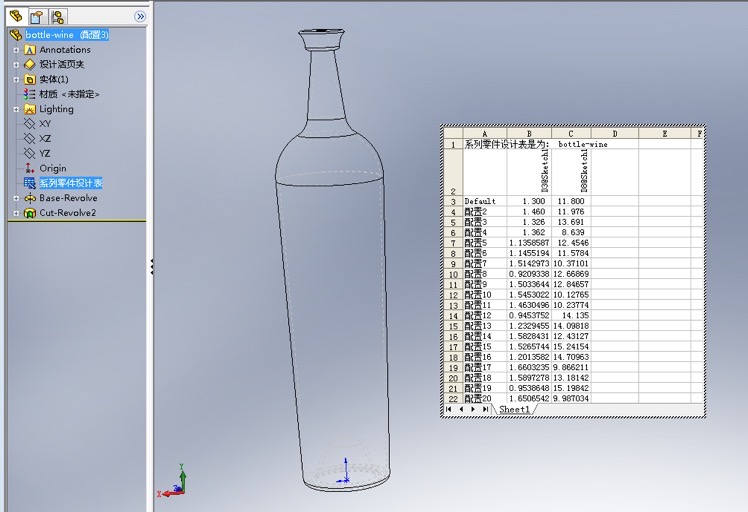

The model design of DOGA is a typical parametric design method. The parameters are defined in an existing model file and can be extracted by API of CAD softwares. We implement DOGA in SolidWorks for industrial and mechanical design of products. The following pictures show an example of 2-degree DOGA of model design and 3-degree DOGA of color design. The degree denotes the number of evolvable parameters. With a larger degree value, product candidates will be much diversified.

Parameter specification is preserved in excel file. Can be modified in SolidWorks.

Left(Upper): Model Design. Right(Bottom): Color Design.

Reference

[1] Hingston, P. F., Barone, L. C., & Michalewicz, Z. (Eds.). (2008). Design by evolution: advances in evolutionary design. Springer Science & Business Media.